21 September, 2023

Windows

Thermal insulation for windows? Does it make sense to buy windows when we already have our old windows? Imagine, dear reader, this situation: it's a Monday evening, early December. First work, then all those errands... The typical Polish winter is already gnawing at you with cold and damp. A sneeze bends you in half. You barely manage to thwart a curse in your throat with a promise of returning home soon. You step into the cage. Discomfort still gnaws at you, but at least you feel no more drops of filthy slurry hanging in the air. You turn the key in the lock. Your whole soul and even the pores on your skin open up to welcome the warmth of home. A barrier of cold rams into your body! The old windows taunt you with flecked seals, curtains gloomily ripple, picked up by the gentle gusts of wind that have let themselves into the flat without invitation. Leaky windows, their flimsy constructions that don't meet modern standards, shamelessly let the cold in and blow away the money spent on heating. You can remedy this. How and how much can you benefit from it?

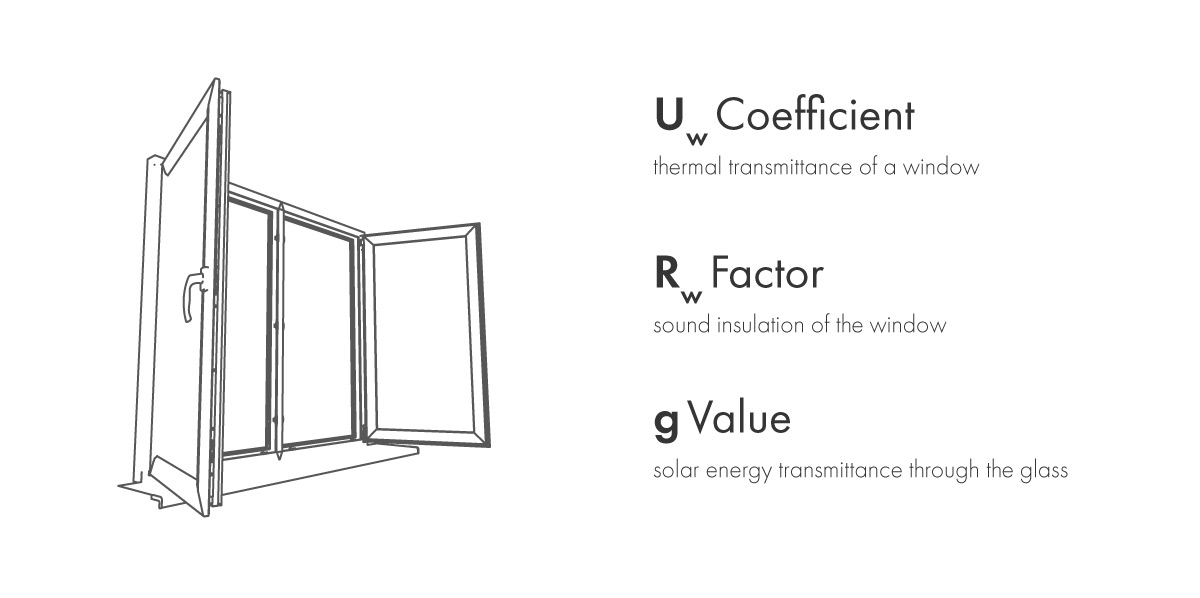

Before we get into specific calculations of how window parameters can affect our heating bills, let's have a brief word about what they are.

By far, the energy transmittance coefficient, abbreviated as Uw, is the most important of all the parameters we need to pay attention to when trying to reduce heating bills. The Uw value indicates the heat that passes through one square metre of window surface.

In practice, it is a little more complicated because the coefficients of Uf and Ug, i.e. the coefficients for the window profile and its glazing, which are components of Uw, are also relevant here. The type of gaskets has its influence, and all thermal parameters are calculated for specific temperature conditions. As a rule of thumb, the larger the glazing area to the profile area, the better the insulation. The unit that expresses the value of the heat transfer coefficient may also be a little befuddling: W/m2K. This is watts per square metre times Kelvin.

Fortunately, the industry standard is to give the Uw for a typical window as a simple fraction, letting us easily compare two systems. When one has a Uw of 1.8 and the other 0.9, we immediately know the latter is losing half as much energy per square metre of window.

Although the acoustic performance of a window does not affect its thermal properties, it is crucial for the comfort of the building's users. It refers to how many decibels the outside noise is reduced.

When we live in a quiet area, an Rw of 30 decibels is sufficient. In a big city, we have the right to expect more, so window constructions offering a reduction of more than 40 decibels are a much better choice. In case of special needs, it's even possible to create windows silencing 10 decibels more. What is more, such can cope particularly effectively with sounds of an unusual frequency.

Another less frequently quoted but still important parameter is the solar factor. It is denoted by the lower-case letter g and is expressed as a scalar value from 0 to 1. It is more convenient to write it down as a percentage.

For example, if g is 0.8 (i.e. 80%), 80% of the solar energy – heat – penetrates through the glazing. Such a value is acceptable when we aim to heat the interior with the sun. However, we may choose glazing with a much lower g if we are apprehensive of too much heat entering through large windows in the summer, which would result in a fortune spent on air conditioning.

The average window owner pays little attention to such parameters. He considers his windows to be airtight, and that's it. The thorough ones may want to consider parameters such as air permeability, wind load resistance and water tightness. They are, to some extent, correlated with the thermal properties of the windows, but a private investor will not focus on them.

Good thermal insulation is not at all easy to achieve. While it is no secret to people who remember old wooden windows of the times gone by and those who own one of the first uPVC windows on the market, younger people may take good insulation for granted. The thermal parameters of old windows were very far from contemporary standards. How do we meet these requirements nowadays?

The most pivotal revolution that has affected windows is the use of glazing units. A simple single glass pane translates into high heat transmission in windows. Glass is a poor insulator. This is why the old windows construction techniques placed one more row of windows behind the first windows.

Such a window sandwich was, in a sense, the great-grandfather of modern glazing units, as it uses a very similar concept: a free space filled with well-insulating air. Nowadays, we usually use even better insulating noble gases, typically argon.

Double glazing is vastly technologically superior and more effective than two old windows blocked together. We build them from two essential elements:

and, in a sense, also a third element:

The system is relatively simple, and what makes the difference is the quality and technology, plus one invisible but crucial one: low-emission coatings.

In double-glazed units, airtight chambers are formed between the panes of glass, which function similarly to a thermos. Regardless, there is rarely a vacuum between them.

The aforementioned low-emission coatings are standard, i.e. thin layers of heat-reflecting metal oxides, without which the modern insulation performance of glazing would remain a dream.

The gas present in the chambers between the panes insulates much better than any solid material, even if it is just plain air. For Eko-Okna, argon has long been the standard, transmitting ⅓ less heat than the nitrogen-oxygen mixture we breathe.

The best gas used to fill glazing units is krypton. Although it reduces thermal conductivity in the chambers by ⅔ compared to air, it is much more expensive, making it recommended in Eko-Okna only in exceptional situations where the customer expects high thermal insulation with minimal thickness of the glazing package.

Until recently, the spacer, i.e. the element joining two panes, was a cause of heat loss, too. It was made of materials that conduct heat well, often steel, which created a thermal bridge. Nowadays, the most common choice of Eko-Okna customers is the so-called warm frame, i.e. a spacer made of a composite in such a way as to reduce the risk of thermal bridges emerging.

The more chambers in a glazing package, the better the performance we can achieve with it. Getting thermal transmission low enough for new construction typically requires glazing units with at least three panes and two chambers.

Last, but by no means least, are the thermal coatings. On the contrary, they are crucial to the performance of the unit. They are applied to at least one pane of glass in the packet and improve its insulation performance by as much as several tens of per cent. Although they are invisible, window insulation would be at a much lower level without them.

The second element besides glazing, which determines the thermal performance of a window, is its profile. Their form can vary greatly. Generally speaking, window profiles are made from four different materials. We can have:

Each of these window types presents itself differently in terms of profiles, as the heat transfer through their materials is different.

The thermal properties of wooden windows are excellent due to the process of preparing the raw material. It is pressed and glued together and then coated with suitable protective coatings. The structure of the wood itself makes the thermal insulation of windows of this type sufficient.

Steel and aluminium are very good conductors of heat. The heat transfer coefficient is so high in them that if we made windows entirely of metal, we might as well dispense with glazing. Maybe not so much, but two things are needed here: multi-chamber profiles and thermal breaks. Windows of this type typically offer a three-chamber profile design. What does this mean? More on that in a moment.

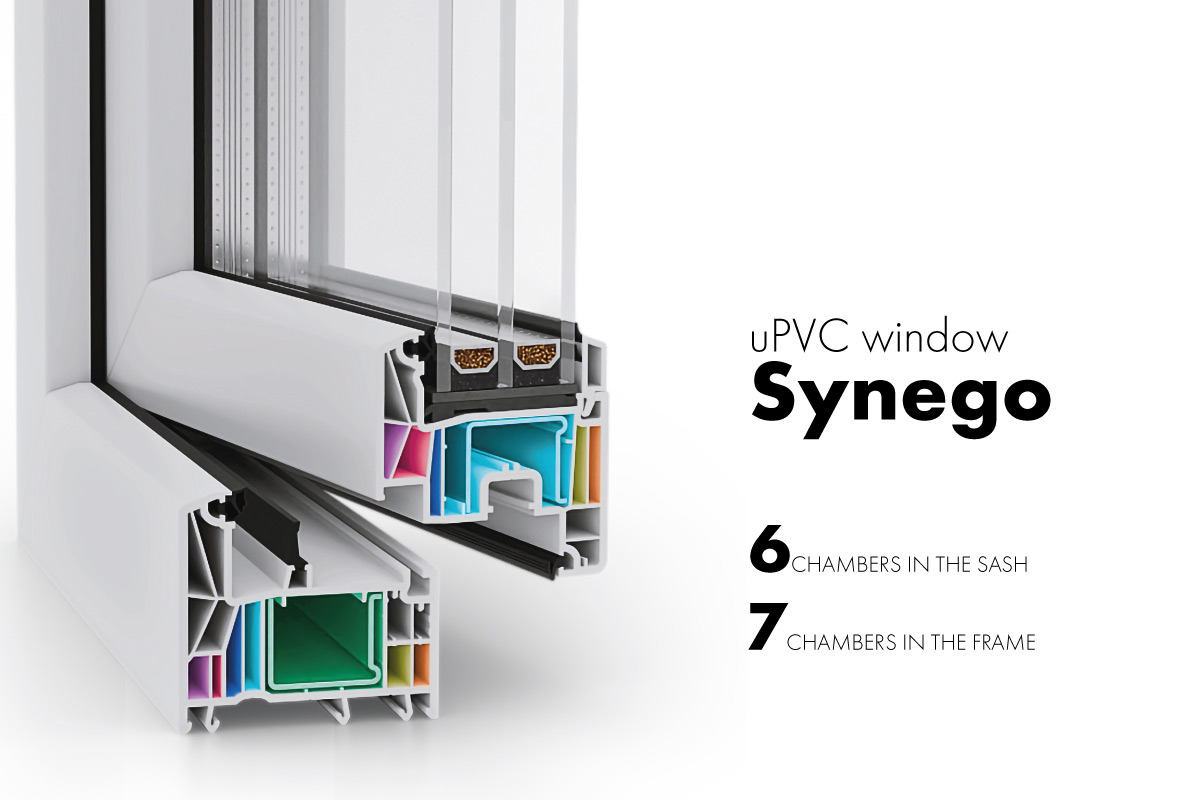

Polymers are relatively effective window insulation, but we still need chambers. This malleable material allows several of them to be created inside a profile, which is one of the main reasons for its widespread use. The general rule is that thermal insulation improves with an increased number of chambers; consequently, most passive windows we manufacture are constructed from uPVC.

The air between the glass pane is a better insulator than the glass itself. The same applies to profiles. This is why we create chambers in them. Each of them means significantly less heat transfer than through a block of material. The best evidence for this is that the best insulating materials, such as polyurethane foams or polystyrene, are actually air bubbles surrounded by a thin layer of insulating substance, respectively polyurethane and polystyrene.

The warmth of a window, the thermal insulation offered by a given design and the thermal comfort it provides is not just a simple function of the number of chambers. To simplify the issue, we can say that within a single type of window with the same glazing, the energy balance of a window will be better the more chambers its profile has.

A so-called thermal break appears in all steel and aluminium products intended for use on external walls. This insert, made of a material with a very low thermal transmittance, breaks the so-called thermal bridge by which heat passes between air-filled chambers.

Why not make the entire window from such a material? In a sense, this is the case with wooden and PVC windows, where no additional thermal break is used. The issue of strength is crucial here. Steel and aluminium are incomparably more durable than the substances used for the thermal breaks in their profiles. A complete window using such technology would be entirely impractical.

Installation methods have a critical impact on the thermal performance of windows. Before we go into specific calculations, we need to mention this.

The traditional window installation technique is still in use today. It was widely employed when the energy rating of a window was of relatively low importance. The walls were not well insulated, nor were the floors and roofs. With the lack of insulation in general, installation methods were negligible.

Nowadays, windows can be very warm and, in addition, adjoining walls have much better thermal performance. This creates the risk of heat bridges, i.e. gaps through which heat escapes at a multiplied rate. They are formed precisely at the junction between the wall and the window.

We had to develop window installation techniques that would decrease the risk of dampness showing in the insulation. This is taken care of by dedicated films that allow the walls to breathe. The warmer the windows, the warmer the house, and the more meaningful proper installation becomes.

We have to start with the fact that even perfect thermal insulation of windows wouldn't result in the elimination of energy loss. A lot of energy loss is unavoidable, and reducing others requires dedicated solutions, such as recuperation systems in the ventilation.

It is not just the windows that are responsible for energy losses. Some buildings have small windows and a large floor area with no basement underneath or a very large roof. Windows in such configurations are responsible for only a minuscule part of the heat loss.

In single-family houses, on the other hand, apart from the ground and top floors, heat transfer to the outside can take place predominantly through windows. In addition, if the ratio of glazing to external walls is very high, poor-quality windows, old window systems or defective windows cause a gigantic increase in heating bills.

All energy loss calculations must be based on certain simplifications and averages. After all, no two buildings are identical, as can best be seen by examining energy passports.

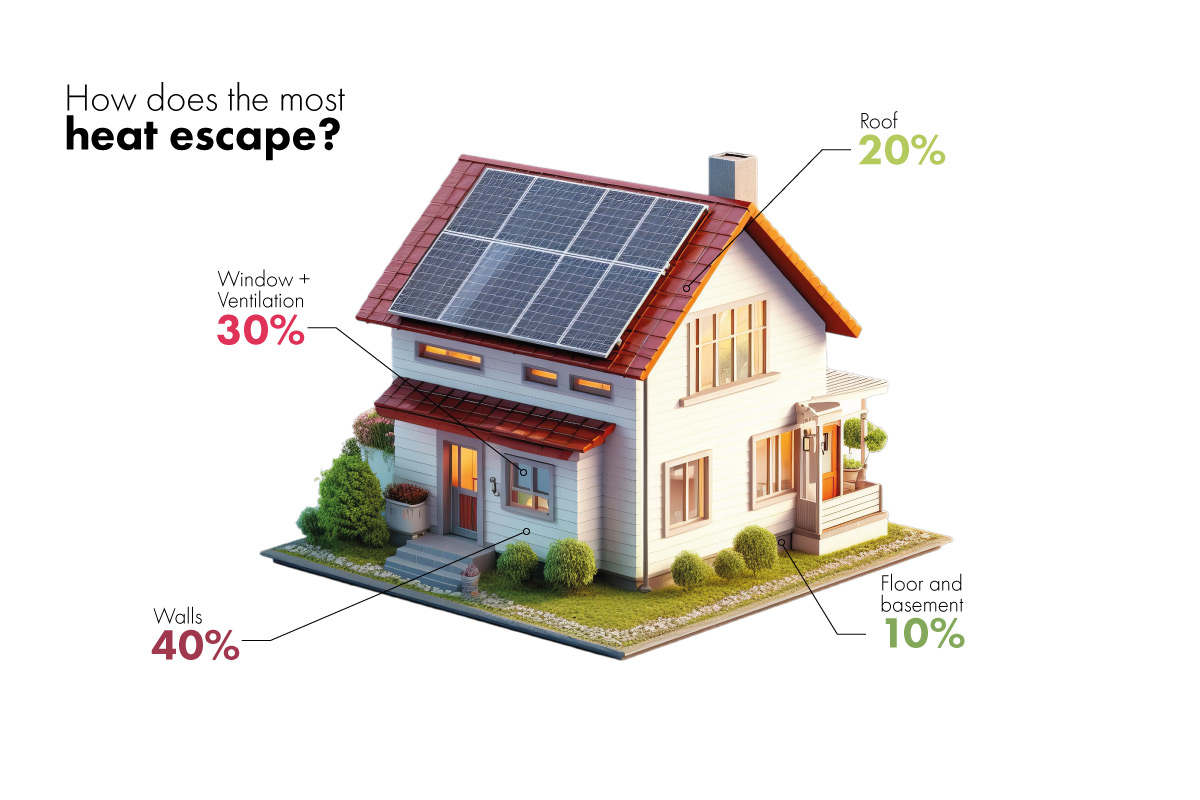

There are four primary routes for heat escape:

In modern construction, the basement is well insulated, if it appears at all, so it should not account for more than 10% of wasted energy. The same applies to the roof, although warm air naturally rises, exacerbating the issue here to up to 20% of total energy waste.

The largest area prone to energy loss is always the walls. In a typical building with standard insulation, walls are responsible for 40% of the total energy loss.

We approach windows and ventilation jointly because - especially if the building has only gravity ventilation – the phenomenon of windows being too airtight can occur. This paradox most often affects renovated buildings where old and leaky windows are replaced with new top-performing ones.

In the past, architects assumed the presence of poor-quality windows in their ventilation calculations. Owners of flats in prefabricated buildings, who are forced to fit ventilators when renovating and replacing windows, usually learn it the hard way. Ventilators help ensure better air exchange when needed without compromising window thermal performance. Inadequate ventilation would result in moisture accumulation. In modern buildings, where calculations assume the presence of adequate windows, this paradox does not exist.

When a heat recuperation system is present in the ventilation, the windows typically account for no more than 30 percent of heat loss.

Finally, let's move on to concrete calculations, which everyone has to do themselves. Following our guidelines, of course.

Let's assume that 30% of the heat energy supplied to a building escapes through windows. Those with old windows or living in multi-family buildings can up this number to 40%, and those in detached houses lower it to 25%. We then calculate the heat loss by multiplying the heating costs we pay by the fraction appropriate to the percentage, i.e.

Cost of heat loss through windows = Total heating cost * 0.3

This is the share of windows and ventilation in the total heat loss of a typical building.

Let's assume that our old windows have a Uw of 2.1 W/m2K. The new windows we plan to install will be some of the best on the market, offering us a Uw of 0.7 W/m2K. This means that the new window, converting, of course, per square metre of its surface, will suffer three times less heat loss.

We know that windows are responsible for roughly 1/3 of the total heating cost, so on this basis, we can calculate how much we can save on heating in our particular situation.

In other words, the hitting bill generated by windows will decrease by 1/3, which for a typical building will translate into a reduction in annual heating expenditure of around 10%. Let us emphasise again that these are very general calculations, dependent on many specific factors. We must always carefully correct it with the data for our house, which we can obtain, among other things, from the energy passport.

The purpose of such calculations is always to decide whether it is worthwhile to replace the windows. This is an investment that requires a substantial financial effort. Using such a calculation can help, all the more so, as it is only a starting point for discussion. There are several other issues to consider:

If we have insulated the building but retained the old windows, the energy efficiency of the windows is likely to degrade significantly due to thermal bridges starting to form.

If our windows are older than ten years, the thermal insulation and air permeability declared in the factory will be far from reality. Nowadays, we can realistically count on up to 15 or more years without any significant deterioration in the performance of windows, but this does not apply to older constructions.

Wear and tear leads to the deterioration of windows. The damage results in leaks. Improperly maintained fittings and gaskets can only seemingly ensure the window sash is sufficiently pressed against the frame.

There are many programs under which we can obtain subsidies for window replacement, e.g. Czyste Powietrze 3.0 in Poland. Thanks to them, the economic calculation can change dramatically.

Over the last decade, the cost of heating buildings has doubled. However, some energy sources have become much more expensive than others. Therefore, if we are using heating that may become significantly more expensive soon, it is worth taking this into account.

Improving the thermal insulation of windows is always a good idea if our current windows don't offer up-to-date performance. We need to remember that this is an investment for years, so even if the windows don't start to pay for themselves after a year or two, they will likely have earned their keep after five years. What's more, every year, energy saving is proving to be a better idea, so we can realistically expect the cost of replacing windows to pay for itself quicker than we think. And let's not forget that new windows can offer us additional functionality, such as better acoustics, protection from excess heat through tinted glass, or they can be prettier.

Hotline: +48 32 459 15 00 Contact for new business customers only. Connection fee in accordance with the operator`s price list.

E-mail: quoteuk@ekookna.com newclientuk@ekookna.com Contact for business customers only.

Eko-Okna S.A.

Kornice, ul. Spacerowa 4

47-480 Pietrowice Wielkie

NIP: 6391813241

KRS: 0000586067